basic parameters

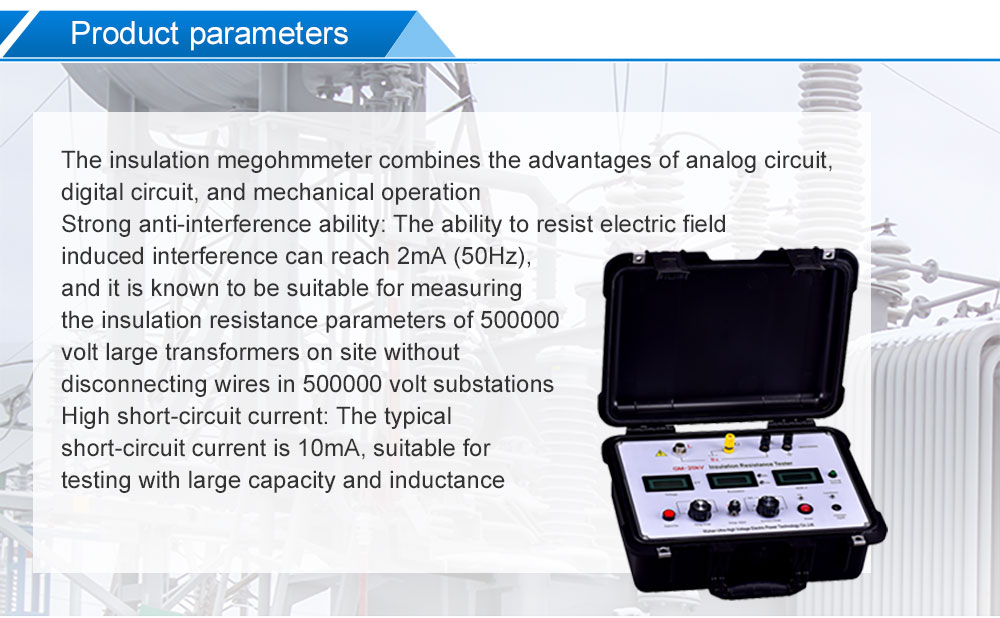

Anti electric field interference capability | 2mA(50/60เฮิร์ต) |

Time reporting and alarm function | The stopwatch displays a maximum value of 19 minutes and 59 seconds. Cycle every 20 minutes. The sound alarm points are 15 seconds, 60 seconds, and per minute Short beep when the point is reached, hold the resistance reading for 3 seconds, if the measured resistance is below the lower limit of the range and the reading is invalid, a continuous sound alarm will be triggered |

Display Table | Three and a half LCD digital meter heads, displaying test voltage, resistance, and time respectively |

แหล่งจ่ายไฟ | Comes with rechargeable lithium battery, powered by DC15V. Charging the battery with a dedicated adapter port for communication (50/60Hz) |

Usage environment | อุณหภูมิ: -20℃ to+40 ℃; Relative humidity: 20% to 90% |

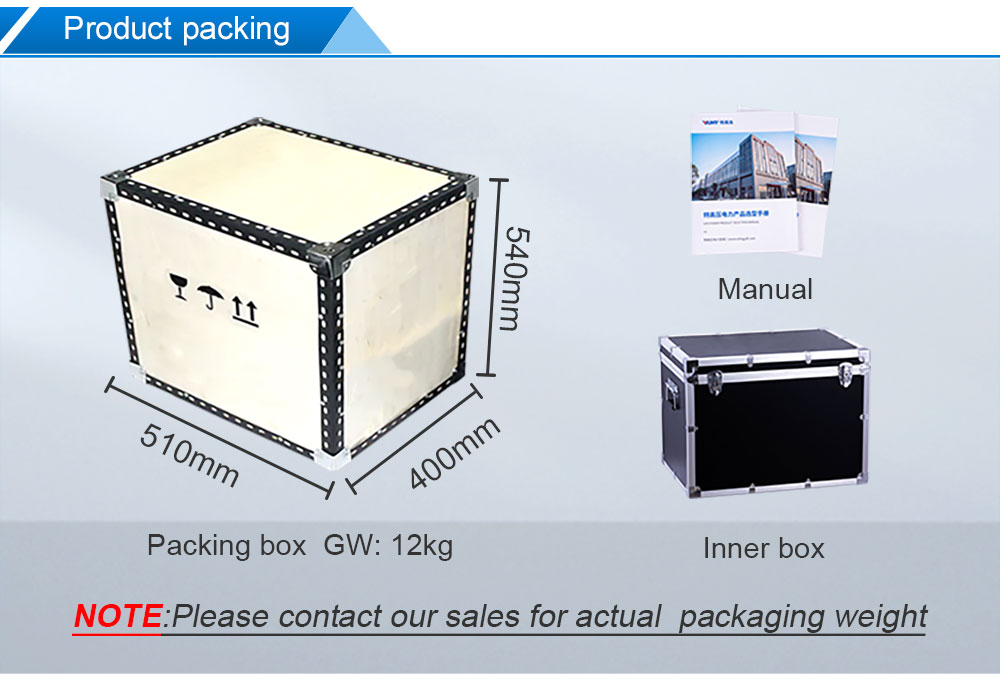

ปริมาณ | 315 × 240 × 180mm (length × width × height) |

quality | 5.5กก |

Nickname: Insulation Resistance Tester; Insulation Meter;Adjustable High Voltage Digital Tester.

working principle

A high voltage digital tester is composed of medium to large scale integrated circuits. This table has high output power, high short-circuit current value, and multiple output voltage levels (with four voltage levels). The working principle is that the DC high voltage generated by the internal battery as a power source through DC/DC conversion is sent from the E pole to the L pole through the tested object, thereby generating a current from E to the L pole. After I/V conversion and division by a divider, the measured insulation resistance value is directly displayed on the LCD.

Precautions and other matters

1. Pay attention to safety‘ L 'is the high voltage end‘ E 'must be grounded!

2. Check the condition of the instrument. Do not use the method of suddenly connecting it when testing the power supply. Instead, connect the resistor before starting the test power supply, and then press the high voltage switch. Try to avoid sparking and discharging during work! Because high-voltage ignition and discharge can easily damage the integrated circuit components of this instrument, as well as the standard resistors or measured objects used for measurement.

3. The battery charging circuit of the instrument is charged according to the constant voltage current limiting charging method, and it takes about 6-8 hours to fully charge each time. A fully charged battery can provide continuous operation of the instrument for 6-8 hours. To ensure the battery life, the storage period of the instrument should be charged every three months.

4. Battery reassembly method: When the nickel hydrogen battery in the instrument is damaged or has poor power supply performance and needs to be reconfigured, the ten batteries that need to be reconfigured should be tested by a battery capacity tester to prove that the capacity is basically the same. Then, each battery should be fully charged before being installed into the GM megohmmeter.